Simply add θ c to the tabled angles at these points. Calculation of reactions courses of forces moments stress deflection and bending angle of the shaft and others.

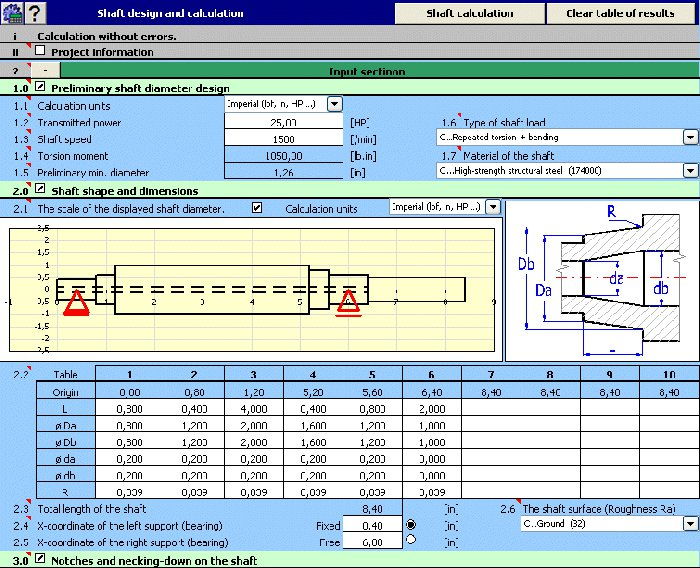

Mitcalc Shafts Shafts Design And Calculation Spreadsheet

Excel Engineering Calculations have both check and design based.

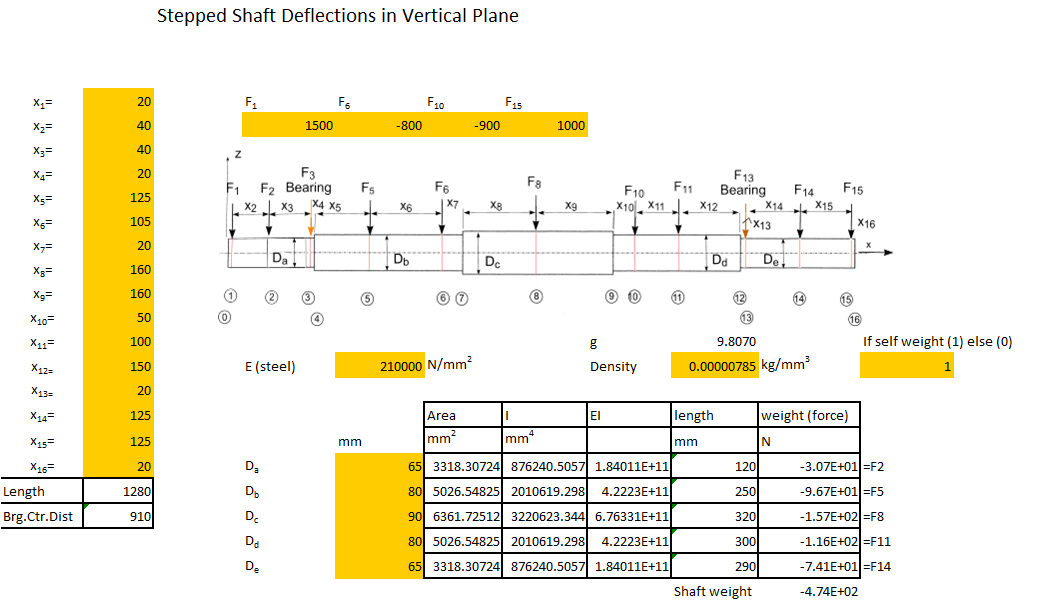

. A shaft between self-aligning bearing A and B is loaded through belt forces applied to a central sheave. Quite often it is impossible to read and check these documents. Shaft Design Problems Step 1.

At point 1 shaft angle 0-0537 mrads -0463mrads 0031 deg. Static and fatigue stress concentrations. Instructions are included in the files.

As a constantly evolving tech company were committed to innovating and challenging existing workflows to save engineers time in their work processes and designs. Excel Engineering Calculations includes many calculation tools in the field of technical industrial engineering. Typically the torque comes into the shaft at one gear and leaves the shaft at another gear.

Machine design calculations have been done with a calculator and written by hand with pen or pencil. Optimizing design values with a calculator is difficult and time consuming. Helps in the design of shafts that are to undergo bending.

A shaft between self-aligning bearing A and B is loaded through belt forces applied to a central sheave. Options of definitions of necking-down recesses grooves and calculation of the relevant coefficients of stress concentration. The calculation is designed for geometrical design and complex strength check of shafts.

Design the shafting concept perform shaft alignment and analyze propulsion vibration efficiently with ShaftDesigner. ShaftDesigner is a CAE shaft calculator software for high-quality marine propulsion fair curve shaft alignment bearing bush calculations torsional vibration analysis axial vibration analysis and whirling vibration analysis. Anchor Propeller Pitched Blade Turbine Chemineer HE-3 Hydrofoil Sawtooth Curved Blade Turbine Straight Blade Turbine Disk Turbine.

This location is for Registered Users Only. MITCalc - Shafts Calculation v120. Many of the concepts one learns in a two course sequence in machinery design culminates in the design of powe r transmission shafts and supporting elements ranging from various drives supporting.

At Point 8 the shaft angle 116mrad-0537mrad 0623 mrads 0036 deg Calculating shaft deflection. Purpose of Calculation Simple calculations for obtaining the natural frequency of traverse vibration of shafts and beams which a. Options of definitions of necking-down recesses grooves and calculation of the relevant coefficients of stress concentration.

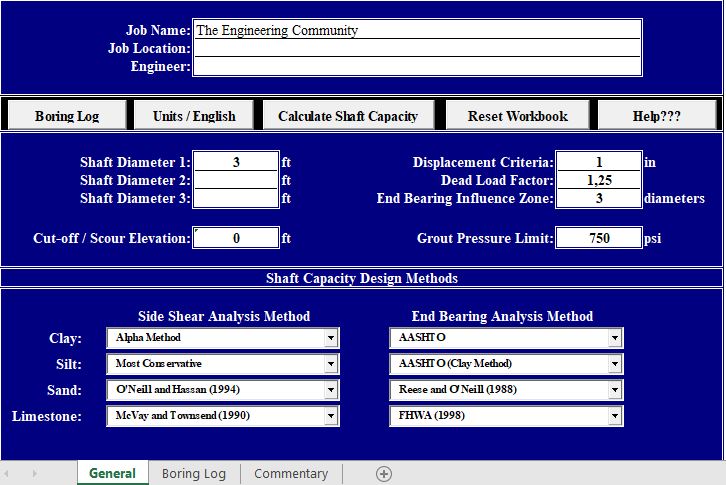

Simple definition of spatial shaft load. Download ODOTs drilled shaft foundation design spreadsheets below. Major shaft diameter Shaft twist along minor diameter deg rad Small diameter d radius r mm Hole d mm Stress Mpa tG Shaft Poisson ratio Shaft modulus E GPa Shear modulus G GPa Undercut design torsion stress MPa Fillet design torsion stress MPa Polar I at fillet shaft diameter mm4 Polar I at undercut shaft diameter mm4.

Up to 24 cash back Shaft designxls. Up to 24 cash back Agitator Design Mech Spreadsheet. 20 Computed diameter to avoid failure.

Excel spread sheets are used to calculate and optimize machine design parameters. If necessary combine the forces. Strength of Materials for Combined Stress in unsymmetrical Bending Case.

The Shaft Design Book Design Charts and Calculations for Torsional Properties of Non-Circular Shafts Premium Membership Required Inertial Energy and Angular Acceleration of a Flywheel Formula and Calculator Flywheels store and release the energy of rotation called inertial energy. Simple definition of installed shafts including hollow ones. Helps in the design of shafts that are to undergo axial loads.

Helps in the design of shafts for critical stability speed. The shaft design tool allows for the following analysis. MEboosts shaft design tool allows for comprehensive analysis of shaft designs.

Simple definition of installed shafts including hollow ones. Download ODOTs drilled shaft foundation design spreadsheets below. Stress life fatigue analysis for infinite life.

Calculate the loads coming from gears belts or chains Step 4. The case study in engineering mechanics vibration machine design and others will be discussed in this paper. The Shaft Calculation Software.

Calculate the bending stress in the shaft. Strength of Materials for Beam Shaft Design and Analysis Case Study 2. Find the torsional stress in the shaft Step 3.

Application is developed in MS Excel is multi-language supports Imperial and Metric units and solves the following main tasks. The mec Engineering Spreadsheets provide easy low cost and professional design spreadsheets for calculation of many mechanical engineering problems using Excel. Shaft diameter D Key slot total width H Key slot depth h Key slot half width y Key slot half width Slot depth y h Slot depth Shaft radius h R Motor Power HP Shaft speed N Allowable shaft stress from above Ssu or Ssy Torque shock load factor Kt Key slot stress factor from graph above Kk Motor shaft torque Tm Section polar moment of inertia J.

If r is less than rcrit the shaf t fails in yield. He a lso has an Excel Spreadsheet model that is available for student use. A Determine and make a sketch showing the stresses acting on the top and side elements T and S.

The shear stress due to the torsion. The calculation is designed for geometrical designs and complex examinations of shafts. 2004 provides a solid treatment of shaft design fairly early in his text.

It guides you quickly and accurately to different design of components fix to any technical glitches or to perform any calculation of any engineering point without requiring any specific expert knowledge. The engineering spreadsheets have been developed with the aim to allow a fast calculation about mechanical design according to the international codes Eurocode and technical literature. Helps in the design of shafts that are to undergo torsion.

90 rows Shaft Design. - Simple definition. SkyCiv offers a wide range of Cloud Structural Analysis and Design Software for engineers.

Broms Soil Parameter Estimation. MITCalc Download Buy. The torque is often relatively constant at steady state operation.

Shaft Design Problems Step 1. The case study in this paper is listing below. MITCalc - Shafts Calculation v120.

Np Graph and User Guide will be provided along with spreadsheet. Shaft Power Geometry Calculate Shaft Diameter Left side shaft diameter SD1 Right side shaft diameter SD3 Center shaft diameter SD2 Torsional shear stress Sxy AT POINT B Max shear stress at B Sxymax Max shear stress Sxy F1 F2 Simply supported edges f K 2πDgwr4 Fixed edges f Balancing Rotating Shafts. Most shafts will transmit torque through a portion of the shaft.

Perhaps you need to login or register. Calculate the torque on the shaft from power Step 2. The programme solves the following tasks.

Calculate the bending moment due to the acting forces. A free body dia-gram of the shaft will allow the torque at any section to be determined. To calculate the shaft anglein thehorizontal planes at the bearing centres Points 1 and 8.

Shaft 1 2 3 Drilled Shaft Design Software

Shaft Capacity Calculation Spreadsheet

Mitcalc Shafts Calculation Standaloneinstaller Com

Shaft 1 2 3 Drilled Shaft Design Software

Design Calculation Using Excel Spreadsheet Download Scientific Diagram

0 comments

Post a Comment